Tobacco production is a highly precise and continuous process that relies heavily on machinery like cigarette making machines, packing machines, filter machines, and tobacco processing equipment. While investing in advanced machinery is essential, the quality and reliability of spare parts are equally critical for maintaining smooth operations. High-quality spare parts ensure longevity, efficiency, and consistent product quality in tobacco production lines.

1. Reducing Downtime and Production Delays

One of the most significant benefits of using high-quality spare parts is the reduction of downtime. Low-quality or incompatible parts can fail unexpectedly, causing production halts and delays. In the competitive tobacco industry, even a short pause in production can lead to lost revenue and missed delivery schedules. Reliable spare parts keep machines running efficiently and minimize interruptions.

2. Maintaining Product Quality

Cigarette production requires precision at every stage, from cutting and blending tobacco to making and packing cigarettes. Worn-out or substandard spare parts can affect the performance of machinery, leading to inconsistencies such as uneven cigarette lengths, misaligned filters, or poor packaging. High-quality spare parts ensure that machines continue to operate at optimal precision, maintaining product consistency and quality.

3. Extending Machinery Lifespan

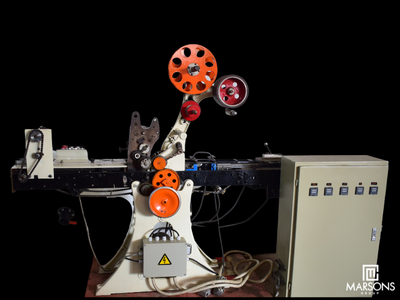

Investing in genuine and durable spare parts significantly extends the lifespan of expensive tobacco machinery. Components such as rollers, blades, motors, and sensors wear over time, but high-quality replacements reduce stress on other machine parts. This minimizes the need for frequent repairs or complete machine replacements, ultimately saving costs in the long term.

4. Enhancing Efficiency and Productivity

Spare parts that meet manufacturer specifications ensure that machines operate smoothly and at peak efficiency. Efficient machinery reduces waste, lowers energy consumption, and speeds up production. By keeping every component in top condition, manufacturers can maximize output without compromising quality.

5. Compliance with Safety and Regulatory Standards

Tobacco machinery must comply with strict safety and quality regulations. Using low-quality or incompatible spare parts can lead to equipment malfunctions, posing safety risks to workers and regulatory violations. High-quality parts ensure that machinery functions safely and remains compliant with industry standards.

6. Cost-Effective in the Long Run

While high-quality spare parts may have a higher upfront cost, they are more cost-effective over time. Frequent breakdowns, production delays, and low-quality outputs from cheap parts can be far more expensive. Investing in reliable components reduces maintenance costs and boosts overall profitability.

Conclusion

High-quality tobacco machine spare parts are a critical component of efficient and reliable tobacco production. They reduce downtime, maintain product quality, extend machinery life, enhance productivity, and ensure safety compliance. For manufacturers aiming to stay competitive in the market, sourcing genuine and durable spare parts is not just a recommendation, it’s a necessity.