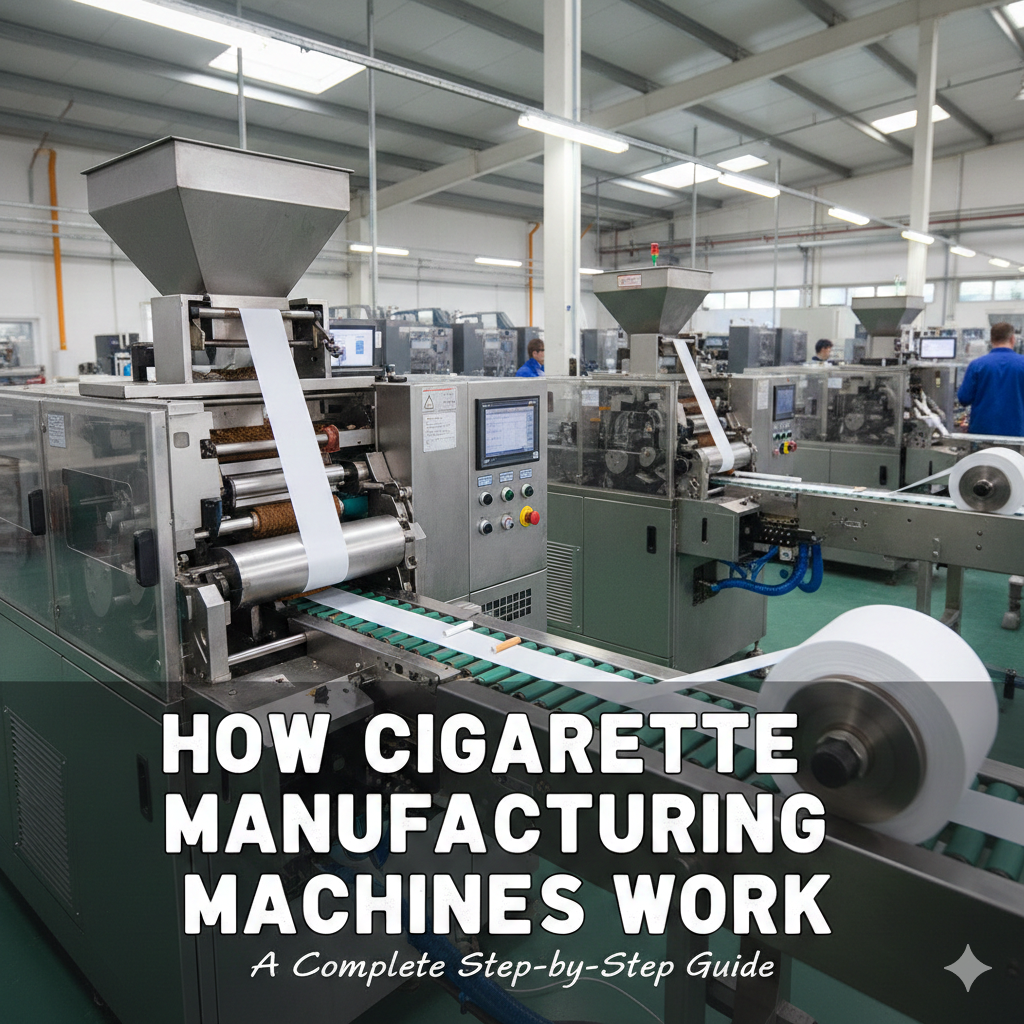

The cigarette industry relies on precision engineering, high speed automation, and strict quality control to produce consistent products at scale. Companies like Marsons Group manufacture advanced cigarette production machinery designed to deliver efficiency, reliability, and high output for tobacco manufacturers worldwide.

This guide explains how cigarette manufacturing machines work, covering every stage from raw tobacco processing to final packaging.

Overview of the Cigarette Manufacturing Process

Modern cigarette production is a continuous, automated process that integrates multiple machines into one streamlined line. The primary stages include:

- Tobacco preparation

- Cigarette rod formation

- Filter attachment

- Quality inspection

- Packing and wrapping

- Cartoning and final packaging

Each stage is carefully controlled to maintain consistent weight, density, and appearance.

Step 1: Tobacco Preparation

The process begins with raw tobacco leaves. These leaves undergo several preparation steps before entering the cigarette maker.

Tobacco Processing Includes:

• Cleaning and removal of foreign materials

• Cutting and shredding into fine strands

• Blending for flavor consistency

• Moisture control for optimal burn rate

The prepared tobacco is then transported automatically to the cigarette making machine through pneumatic feeding systems.

Step 2: Cigarette Rod Formation

This is the core function of the cigarette manufacturing machine.

The machine performs the following tasks:

• Distributes shredded tobacco evenly on a moving belt

• Compresses the tobacco into a continuous rod

• Wraps the rod with cigarette paper

• Applies adhesive to seal the paper

• Cuts the continuous rod into standard cigarette lengths

Modern high speed machines can produce thousands of cigarettes per minute with precise weight control systems.

Key Parameters Controlled During Rod Formation

| Parameter | Purpose | Impact on Product |

|---|---|---|

| Tobacco Weight | Ensures consistency | Uniform smoking experience |

| Paper Tension | Maintains shape | Prevents defects |

| Moisture Level | Controls burn rate | Improves quality |

| Rod Density | Structural integrity | Smooth draw |

Advanced sensors constantly monitor these parameters to reduce variation.

Step 3: Filter Attachment

After the cigarette rods are formed, they move to the filter attachment machine.

This stage includes:

• Feeding pre made filters

• Aligning filters with cigarette rods

• Wrapping tipping paper around the joint

• Cutting into individual filtered cigarettes

High precision alignment ensures proper airflow and a secure bond between filter and tobacco rod.

Step 4: Quality Inspection Systems

Modern cigarette manufacturing lines integrate automated inspection technologies.

These systems check for:

• Weight accuracy

• Filter positioning

• Proper paper sealing

• Defective rods

• Incorrect length

Rejected products are automatically removed from the production line to maintain quality standards.

Step 5: Cigarette Packing Process

Once approved, cigarettes move to the packing machine.

The packing process involves:

• Arranging cigarettes into groups

• Wrapping with foil or inner liner

• Placing into printed packs

• Sealing the pack

• Applying tax stamps where required

High speed packing machines synchronize perfectly with production output to avoid bottlenecks.

Step 6: Cartoning and Final Packaging

In the final stage:

• Individual packs are grouped into cartons

• Cartons are wrapped and sealed

• Barcodes and batch numbers are printed

• Finished cartons are prepared for distribution

This entire process operates continuously with minimal human intervention.

Automation and Technology in Modern Cigarette Machines

Today’s cigarette manufacturing machines use advanced automation technologies including:

• PLC control systems

• Touchscreen human machine interfaces

• Real time monitoring software

• Automatic lubrication systems

• Energy efficient drive systems

These innovations increase productivity, reduce waste, and improve operational safety.

Benefits of Using Advanced Cigarette Manufacturing Machines

Manufacturers gain significant advantages when using modern equipment:

Higher production speed

Lower labor costs

Reduced material wastage

Consistent product quality

Improved regulatory compliance

Better return on investment

Choosing the right machinery partner ensures long term production reliability.

Choosing the Right Cigarette Manufacturing Machine

Before investing in a production line, manufacturers should consider:

Production capacity requirements

Factory space availability

Level of automation needed

Maintenance support

Spare parts availability

Technical training and after sales service

Working with an experienced manufacturer ensures the equipment matches your operational goals.

Frequently Asked Questions

How many cigarettes can a modern machine produce per minute?

High speed machines can produce between 2000 to 8000 cigarettes per minute depending on model and configuration.

What is the lifespan of a cigarette manufacturing machine?

With proper maintenance, machines can operate efficiently for 15 to 25 years.

Are cigarette machines fully automated?

Most modern systems are highly automated but still require trained operators for supervision, quality checks, and maintenance.

How important is maintenance in cigarette production?

Regular preventive maintenance is essential to reduce downtime, maintain quality, and extend machine life.

Can production lines be customized?

Yes, manufacturers like Marsons Group offer customized solutions based on capacity, automation level, and specific factory needs.

Conclusion

Cigarette manufacturing machines combine precision engineering, automation, and strict quality control to deliver high volume production with consistent quality. From tobacco preparation to final packaging, each stage is carefully synchronized for maximum efficiency.

If you are looking to upgrade your production line with reliable and high performance cigarette manufacturing machines, contact Marsons Group today to discuss your requirements and get expert guidance tailored to your factory needs.