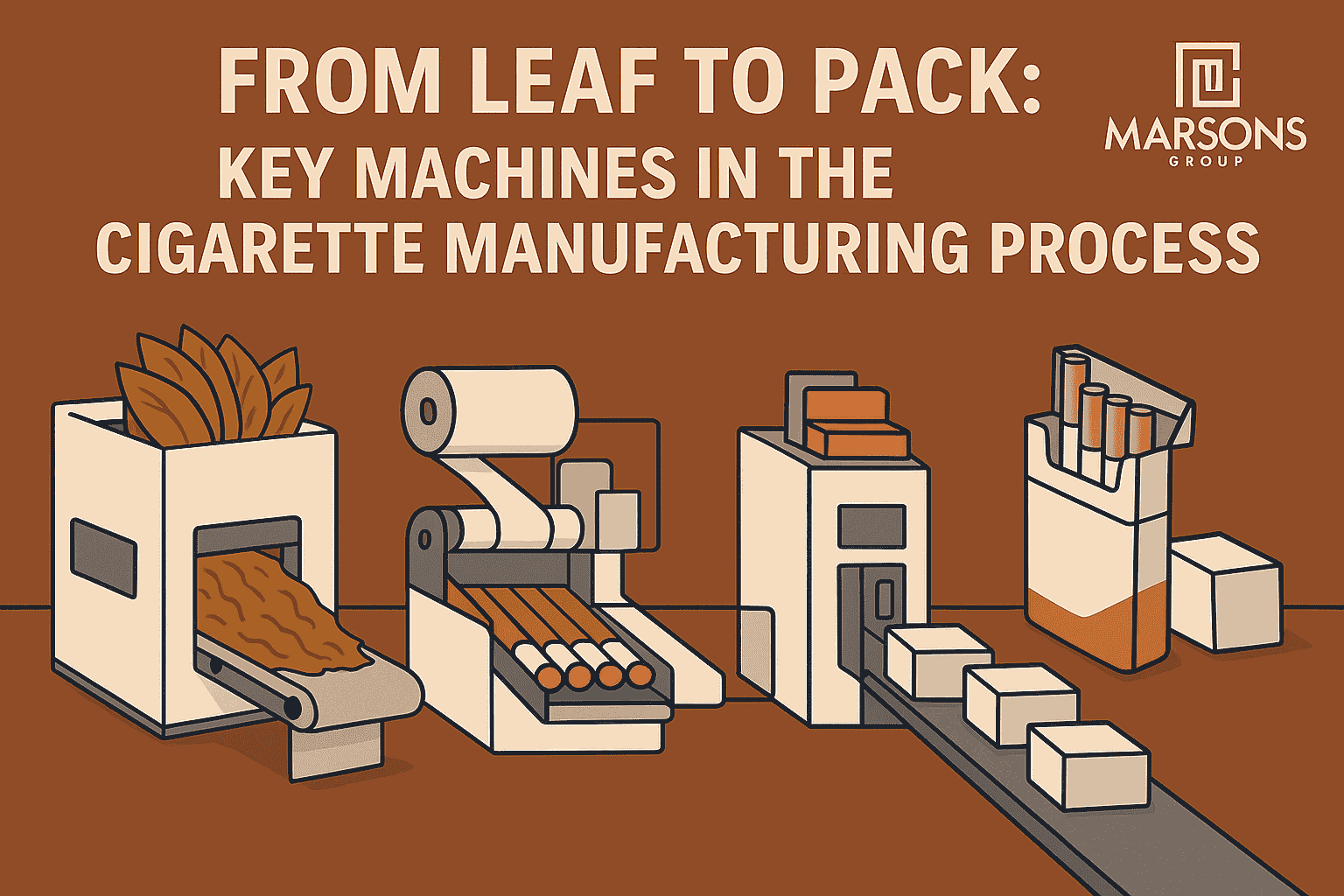

The cigarette industry remains one of the largest and most mechanized sectors of the global economy. Despite growing discussions around health and regulations, the production of cigarettes continues at an enormous scale, with billions of sticks manufactured daily in factories worldwide. But behind every neatly packed cigarette lies an intricate process that transforms raw tobacco leaves into a refined consumer product.

This transformation is made possible by advanced tobacco machinery, which ensures speed, consistency, and quality. From conditioning raw tobacco leaves to producing filters, from rolling sticks to final packaging, each stage relies on highly specialized machines. For cigarette manufacturers and suppliers, understanding the cigarette manufacturing process and the key machinery involved is crucial for achieving efficiency, reducing costs, and meeting international quality standards.

1. The Cigarette Manufacturing Process: An Overview

The cigarette manufacturing process involves multiple carefully monitored steps. Each stage ensures that the final product not only meets consumer expectations but also complies with strict industry regulations.

The major stages include:

Tobacco Preparation – Raw leaves are processed, cut, flavored, and conditioned to prepare them for rolling.

Cigarette Making – Cigarette rods are formed, filters are attached, and sticks are cut to the desired length.

Cigarette Packing – Finished cigarettes are packed into branded packets, wrapped, and boxed for distribution.

Quality Control – Automated machines check each stick for weight, draw resistance, and uniformity.

At every point, cigarette manufacturing machinery plays an essential role, enabling factories to produce millions of cigarettes per day with remarkable precision.

2. Primary Processing Machines: From Leaf to Cut Tobacco

Before tobacco can be rolled into a cigarette, it must undergo primary processing. This stage transforms raw, cured tobacco leaves into cut filler—the fine strands you see inside a cigarette.

Tobacco Conditioning Machines

These machines restore the right moisture levels in dried tobacco.

Conditioning makes leaves flexible, preventing breakage during cutting.

Uniform conditioning ensures consistent smoke quality.

Cutting Machines

High-speed cutters shred tobacco leaves into thin, even strands.

Precision cutting is crucial, as strand size directly affects cigarette burn rate and flavor.

Modern cutters can handle tons of tobacco per hour, making them vital in large-scale production.

Drying & Flavouring Machines

After cutting, the tobacco is passed through dryers to reach the correct moisture balance.

Flavouring machines add aromas, humectants, or menthol to enhance smoking experience.

Automation ensures even application across large batches.

Why this stage matters:

Without proper primary processing, cigarettes may taste inconsistent, burn unevenly, or fail to meet international quality benchmarks.

3. Secondary Processing Machines: Cigarette Making

Once the tobacco is cut and conditioned, it moves to the secondary processing stage, where cigarettes are formed. This stage is highly mechanized, with machines capable of producing up to 20,000 cigarettes per minute.

Cigarette Making Machines (CMMs)

These machines roll shredded tobacco into a continuous rod wrapped in cigarette paper.

The rod is then cut into uniform sticks.

Some advanced machines combine tobacco rod formation and filter attachment in one system.

Filter Making Machines

Filters, usually made from cellulose acetate, are produced separately.

Machines ensure precision size and density for controlled smoke filtration.

Filters significantly influence smoking smoothness and tar/nicotine delivery.

Filter Attaching Machines

The cigarette rod and filter are joined using tipping paper.

Accuracy is essential—misaligned filters reduce product quality.

High-speed machines can attach thousands of filters per minute.

Rod Cutting and Trimming

The long cigarette rods are cut into standard lengths (usually 84mm for king-size).

Trimming ensures a clean finish at both ends.

Efficiency Impact:

Modern cigarette making machines have revolutionized production, cutting labor costs, reducing waste, and guaranteeing uniformity across millions of sticks.

4. Cigarette Packing and Wrapping Machines

Once cigarettes are produced, they must be carefully packed and sealed. Packaging not only protects the product but also serves as a powerful branding tool.

Cigarette Packaging Machines

These arrange cigarettes into packs (commonly 10s, 20s, or 25s).

Machines align sticks perfectly to avoid breakage.

Automated systems can produce thousands of packs per hour.

Wrapping Machines

Finished packs are wrapped in cellophane or film.

Wrapping ensures freshness, prevents contamination, and supports brand presentation.

Tear tape is often included for consumer convenience.

Cartoning & Case Packing Machines

Individual packs are grouped into cartons (usually 10 packs per carton).

Cartoning machines automatically seal and label cartons for distribution.

Large factories use robotic systems for palletizing cartons, ready for shipping.

Why it matters:

Packaging protects product quality and plays a vital role in marketing. With global competition in the tobacco sector, efficient cigarette packing machines help companies deliver products faster and more reliably.

5. Quality Control & Inspection Machines

Quality control is non-negotiable in cigarette manufacturing. Automated inspection systems ensure every cigarette meets strict standards before leaving the factory.

Weight & Density Control

Machines check if each stick contains the correct amount of tobacco.

Underweight cigarettes may burn too fast; overweight ones may alter taste.

Draw Resistance Testing

Ensures cigarettes provide a consistent smoking experience.

Machines test airflow resistance to maintain smooth draw.

Ventilation & Filter Testing

Verifies the filter’s performance and ventilation holes.

Ensures compliance with tar and nicotine regulations.

Vision Inspection Systems

High-speed cameras detect defects such as paper tears, filter misalignment, or loose ends.

Defective sticks are automatically removed.

Importance:

Strong quality control protects brand reputation and ensures compliance with government health regulations.

6. Modern Innovations in Tobacco Machinery

The tobacco industry is not immune to technological progress. Modern cigarette factory equipment is increasingly automated, sustainable, and digital.

IoT-Enabled Machines: Factories use smart sensors to monitor machine performance in real time.

Energy-Efficient Systems: New dryers and cutters consume less energy, reducing costs.

Sustainability Features: Machines that minimize tobacco waste and optimize material usage.

High-Speed Automation: Cutting-edge machines can produce up to 30,000 cigarettes per minute.

Smart Packaging: Advanced systems integrate QR codes, anti-counterfeit labels, and eco-friendly wrapping materials.

7. Choosing the Right Cigarette Manufacturing Machinery

For manufacturers, investing in the right machinery can define success. Key factors to consider include:

Production Capacity – High-volume factories need machines that can handle large-scale production.

Technology – Modern, automated systems reduce costs and improve efficiency.

Supplier Reliability – Choosing experienced suppliers ensures long-term support.

Maintenance & Spare Parts – Availability of after-sales service and spare parts is critical.

Cost vs. Efficiency – Balancing upfront investment with long-term returns.

By selecting the right machinery, tobacco factories can ensure smooth operations and maintain competitiveness in a rapidly changing industry.

Conclusion

From the moment raw tobacco leaves enter the factory to the time neatly wrapped packs are shipped out, cigarette manufacturing machinery drives the entire process. Each machine—from cutters and dryers to rod makers, filter attachers, and packagers—plays a critical role in ensuring efficiency, quality, and consistency.

In today’s competitive market, manufacturers cannot rely on outdated methods. Embracing modern, high-speed, and energy-efficient tobacco machinery is essential to meet demand, reduce costs, and comply with global standards.

The journey from leaf to pack is a testament to how far industrial engineering has come. For tobacco manufacturers, staying updated with the latest machinery is not just about efficiency—it’s about ensuring long-term success in a global industry.